Welcome aboard!

- Teacher: TST Moodle Admin

This course is based on the DEP600 weld control pendant. This course will familiarize the student with all of the features and functions of the DEP user interface.

| 1. Physical Connection |

| o Hardware Overview |

| o Connecting DEP to Timer |

| o Connecting DEP to Control |

| 2. Home Menu |

| o DEP Configuration |

| o Ethernet Option |

| o Serial Connection |

| o Common Connection Issues |

| 3. DEP Main Display |

| o Weld Record |

| o Heat Display |

| o Fault Reset |

| o Graphing |

| 4. Program Mode |

| o Edit Schedule |

| o Edit Setup Parameters |

| o Edit Stepper |

| o Spot Editing |

| 5. Status Mode |

| o Review Stepper |

| o I/O Status |

| o Hardware Status |

| 6. Configuration |

| o Reload Defaults |

| o I/O Configuration |

| o Network Configuration |

| 7. Backup |

| o Backup/Download |

| o Restore |

| o Download (USB) |

This course is based on the Gen6A MFDC weld control and is designed to familiarize new users to use and maintenance of the unit.

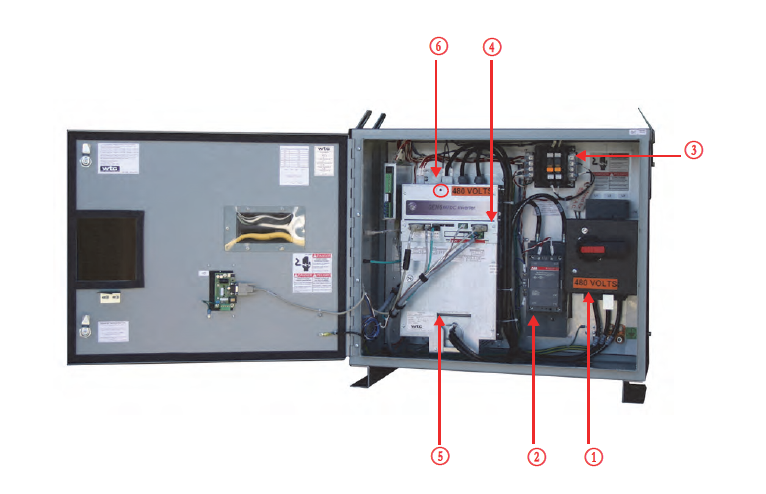

| 1. Cabinet Hardware Overview |

| 2. Processor Overview |

| 3. I/O Interface Overview (DeviceNet, EtherNet, Profinet, Discrete) |

| 4. I/O Bit Mapping |

| 5. Programming Setup Parameters |

| 6. Fault Overview and Diagnostics |

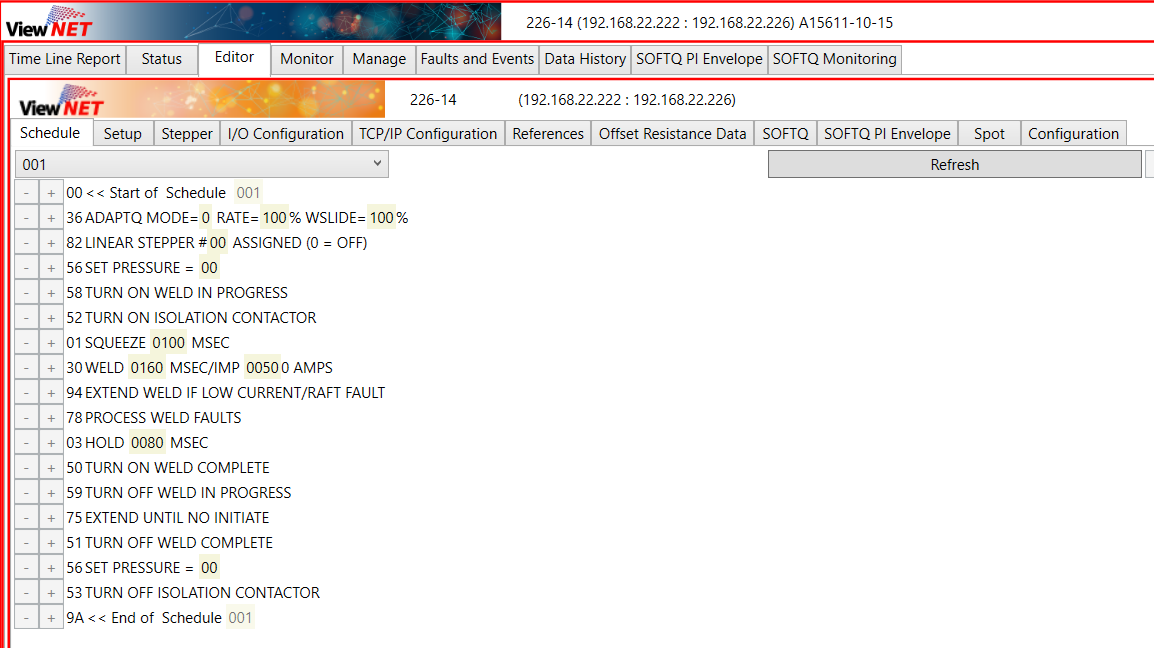

| 7. Inserting, Editing and Deleting Functions |

| 8. Programming Linear Steppers |

| 9. Data Entry Panel (DEP-600) Overview |

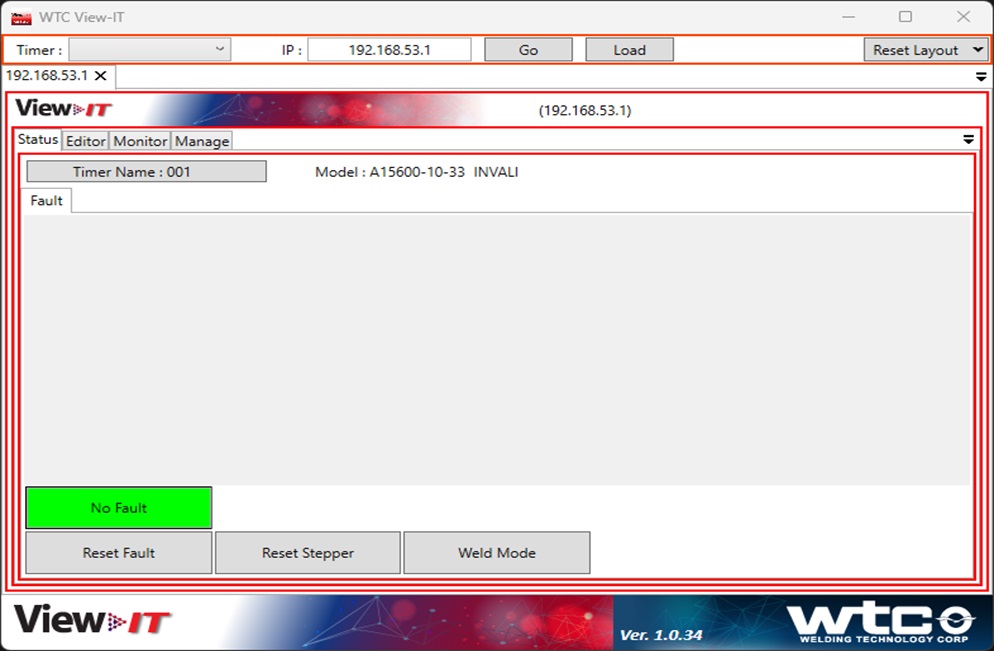

| 10. View-Net/View-It Software Overview |

| 11. Basic Resistance Spot Welding Concepts |

This training covers the ViewR industrial computer. The ViewR can connect to up to 48 weld controls. The ViewR provides a platform looking forward to a Industry 4.0 approach to manufacturing.

| 1. View-R Installation, Setup and Configuration |

| 2. Specification Overview |

| 3. Power Connections |

| 4. Network Architecture |

| 5. Configuration Web Page |

| 6. Licensing Web Page |

| 7. Weld Control Management Web Page |

| 8. Troubleshooting |

| 9. User Logins |

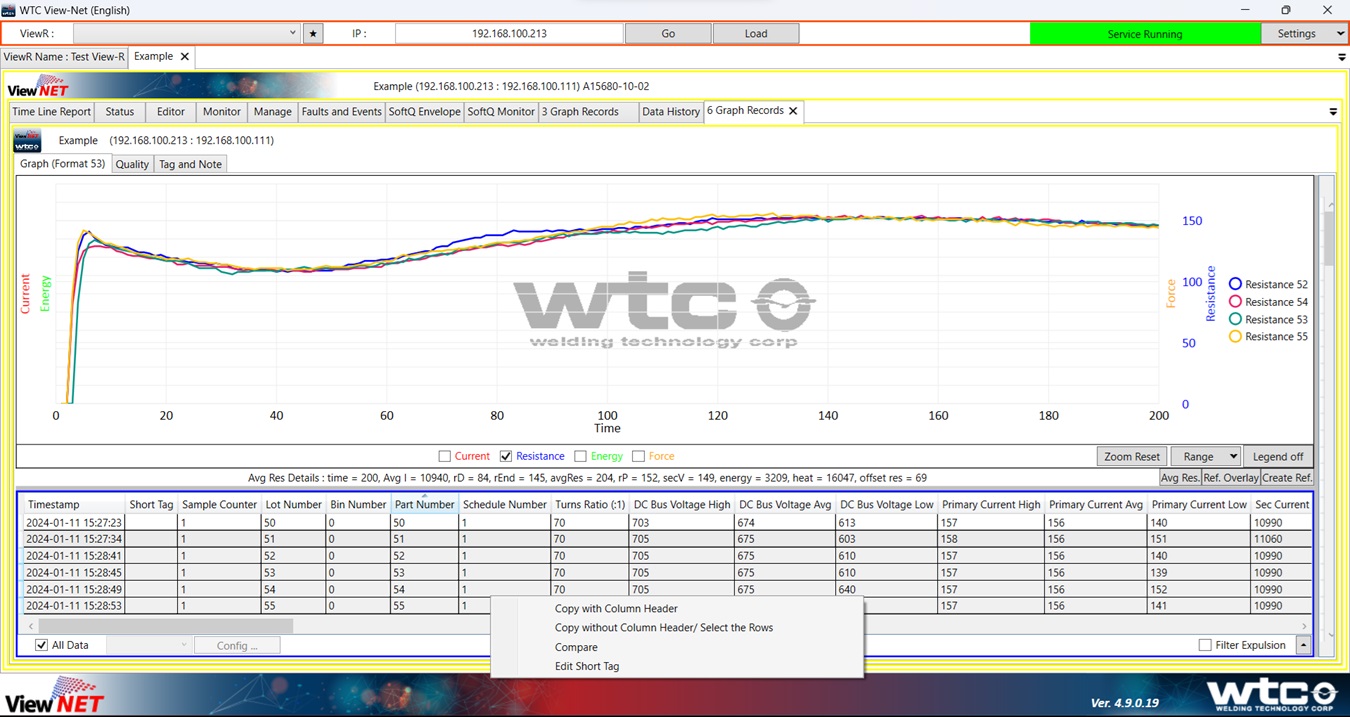

ViewNet is the user interface software that connects to the ViewR hardware. The ViewNet connects to the ViewR and can communicate and monitor the weld controls connected to the ViewR.

| 1. View-Net Interface Review |

| 2. Adding a View-R |

| 3. Layout Adjustment |

| 4. Data Collection Services |

| 5. User Logins |

| 6. Service Preferences |

| 7. Tab Navigation |

| 8. Generating Backup Files |

| 9. Upgrading Software |

| 10. Weld/Graph Data Overview |

| 11. Troubleshooting |

This course is based on the WTC weld control freeware. The user interface software allows access to most features of the WTC weld control.

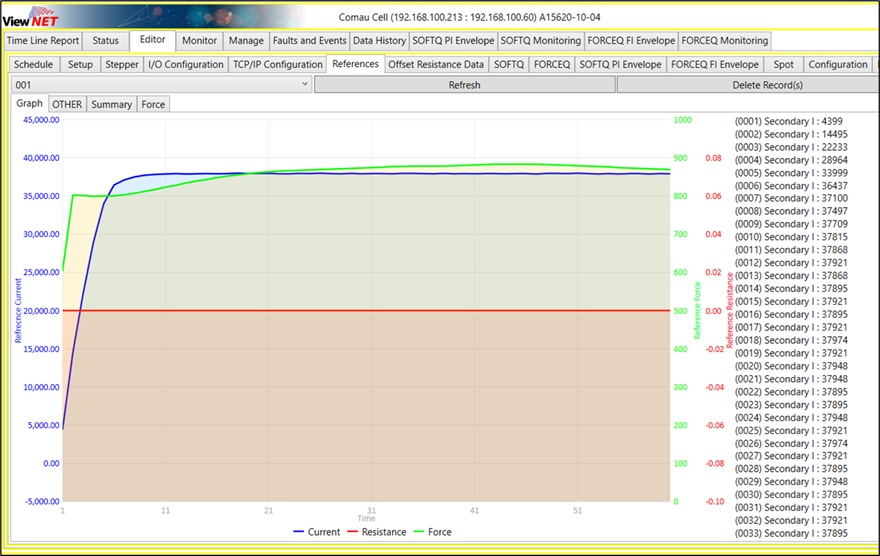

This training is based on the SoftQ RAFT application. SoftQ allows the weld control processor to utilize a series of process analysis algorithms that provide useful information in the state of the welding tool and the quality of the welding process.

| 1. Install / Config / Operation of ViewNet Software |

| 2. Tip (Voltage Sense) Wire Installation |

| 3. Weld Timer Connections |

| 4. Tip Dress Validation |

| 5. Resistance Measure |

| 6. Reference Weld |

| 7. Spot History |

| 8. Expulsion Detection Using Resistance |

| 9. Process Integrity (PI) Envelope |

| 10. Tooling Integrity (TI) Envelope |

| 11. Nugget Integrity (NI) Envelope |

| 12. SoftQ Monitoring Setup |

| 13. Quality Tab |

| 14. Fault Configuration |

| 15. Troubleshooting |

This training course is based on the RAFT AdaptQ application. AdaptQ uses many of the RAFT variables and algorithms used by SoftQ. AdaptQ uses the algorithms to adjust the welding process while it is happening.

| 1. RAFT (Resistive Adaptive Feedback Technology) Theory Overview |

| 2. Install / Config / Operation of ViewNet Software |

| 3. Tip (Voltage Sense) Wire Installation |

| 4. Weld Timer Connections |

| 5. Tip Dress Validation |

| 6. Constant Current Weld Schedule Setup |

| 7. Resistance Measure |

| 8. Reference Weld |

| 9. Enabling Adaptive Mode |

| 10. Spot History |

| 11. Expulsion Detection Using Resistance |

| 12. AdaptQ Functions Overview |

| 13. Process Integrity (PI) Envelope |

| 14. Tooling Integrity (TI) Envelope |

| 15. Nugget Integrity (NI) Envelope |

| 16. SoftQ Monitoring Setup |

| 17. Quality Tab |

| 18. Fault Configuration |

| 19. Troubleshooting |

The ForceQ Training module is designed to introduce and guide the end user to setup ForceQ data analysis tools. This course starts with the installation, setup and programming of the ViewNet software. Next, important topics regarding resistance spot welding and weld graph analysis are discussed to guide the user to develop a good welding process.

1. Hardware and Software Overview

2. Pre-Requisites and Setup

5. RAFT Tab

6. ForceQ Programming Tools

7. Troubleshooting

This section presents a survey of the quality and effectiveness of a service call.

If you have any questions please contact me or post them here. If you have a question others may have the same question.

If you have any questions, please post them here or email sight admin at adouglas@weldtechcorp.com.