This training is based on the SoftQ RAFT application. SoftQ allows the weld control processor to utilize a series of process analysis algorithms that provide useful information in the state of the welding tool and the quality of the welding process.

| 1. Install / Config / Operation of ViewNet Software |

| 2. Tip (Voltage Sense) Wire Installation |

| 3. Weld Timer Connections |

| 4. Tip Dress Validation |

| 5. Resistance Measure |

| 6. Reference Weld |

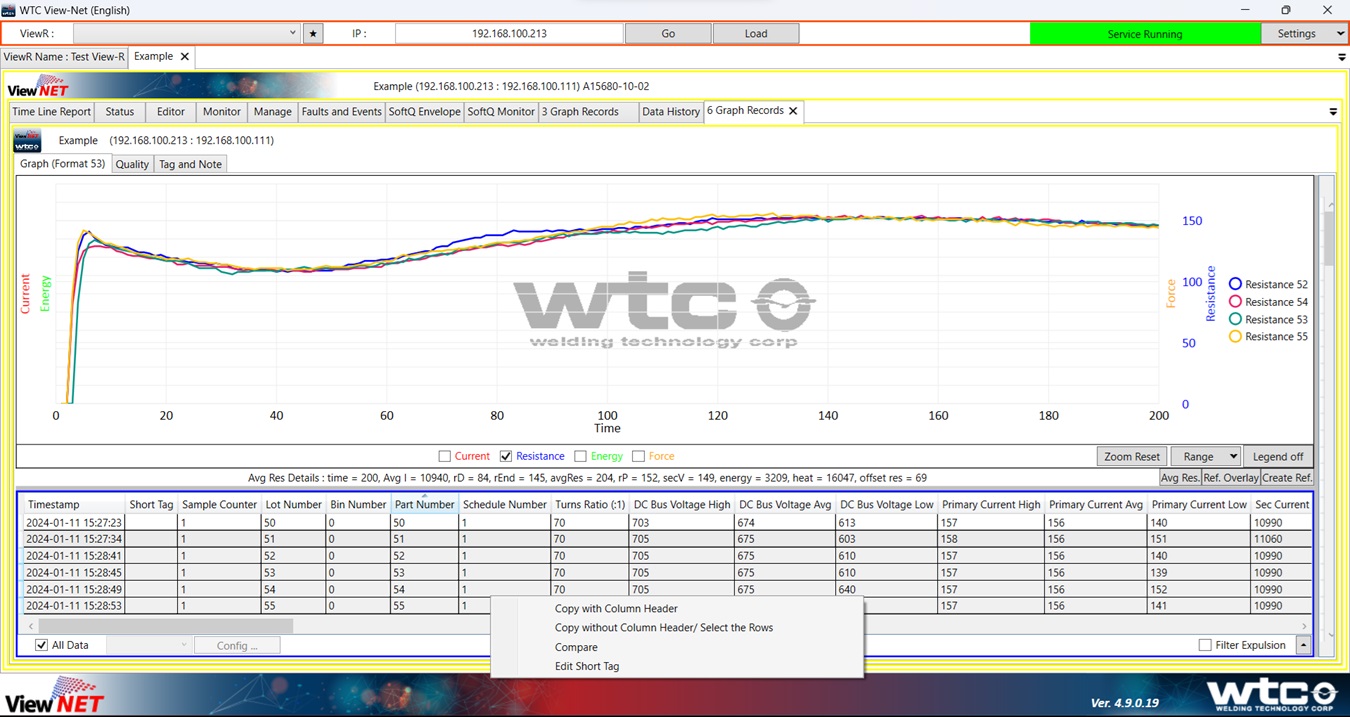

| 7. Spot History |

| 8. Expulsion Detection Using Resistance |

| 9. Process Integrity (PI) Envelope |

| 10. Tooling Integrity (TI) Envelope |

| 11. Nugget Integrity (NI) Envelope |

| 12. SoftQ Monitoring Setup |

| 13. Quality Tab |

| 14. Fault Configuration |

| 15. Troubleshooting |

- Teacher: TST Moodle Admin